3D-Fuel Pro PLA (APLA+) - various colors

Made from NatureWorks™ 3D870 Ingeo PLA, 3D-Fuel's ProPLA is a third-generation formula for 3D-Printing, and... it's made from corn!

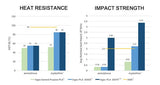

Pro PLA is engineered and designed specifically with 3D printing in mind. Pro PLA was designed with the high impact strength needed in industrial applications to meet the growing demand by companies for a material with the properties of ABS, but the printability of PLA. Without any annealing/heat treating, Pro PLA displays impact strength levels at 8 times that of standard PLA and 1.5 times that of ABS. Annealing Pro PLA gives it over 12x the impact strength of standard PLA and over twice that of ABS.

Annealing (Heat Treating) Info

To get the maximum strength out of your parts printed in Advanced PLA, 3d-Fuel recommends a post-annealing procedure that could be done in an oven or toaster oven at a range of 176°F-266°F (80°C- 130°C) to promote increased crystallization and further improve the heat deflection temperature.

For best results:

- Preheat the oven or toaster oven.

- Place print on room temperature baking sheet.

- Place baking sheet into oven/toaster oven.

- Wait 30-60 minutes for annealing to complete (You may see the print take on a milky/matte/opaque color transformation.)

- Turn the oven off.

- Wait for oven to cool before removing print.

- Shrinkage and/or warping may occur. The degree of shrinkage/warping depends heavily on the part geometry. Items with extended sections can also be subject to some movement during this process. Only testing will show how any particular print will hold up.

Following this procedure will provide a stronger and more temperature resistant part. This will allow you to reach the full potential of the filament and printing process for your part.

| PRO PLA (APLA+) | |

| Recommended Extrustion Temperature: | 210°C - 240°C |

| Recommended Nozzle size: | Any Size |

|

Recommended Retraction Settings: |

.5mm per 0.1mm of nozzle diameter (ie. 2.5mm retraction when using a 0.5mm diameter nozzle) |

|

Recommended Print Surface: |

Hot - Glass heated to 60-70°C or 50°C with a very light coat of pva glue. (if using any glue, or hairspray with a heated bed use it very sparingly. PLA will stick very well and can be difficult to remove without braking or chipping the glass.

|

|

Print Cooling fan? |

Print cooling fans are highly recommended with PLA filament and usually result in a very noticeable improvement in the appearance of the print. Print cooling fans also greatly improve the ability to bridge gaps and print overhanging areas without support when using PLA filaments. |